Mantainance

The operation and maintenance of solar power systems including O&M of equipment at the Station side and equipment at the Solar Power Plant side (“PV Plant”) is becoming difficult due to technical improvement in solar power industry. In the event of any breakdown or failure in the PV Plant, the operation of the Plant will be negatively affected and it will take a certain amount of time or long term to fix the problem, resulting in reduced energy generation and loss of accumulated profits.

In addition, failures can cause significant damage to equipment, people, the immediate vicinity and/or end users of electricity. Accordingly, in order to prevent risks, operation and maintenance activities, including but not limited to, are necessary: Routine maintenance and corrective maintenance of equipment operation (if an emergency occurs).

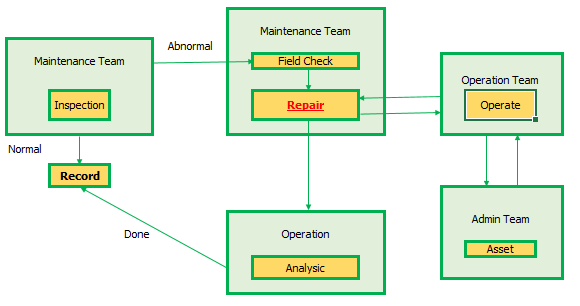

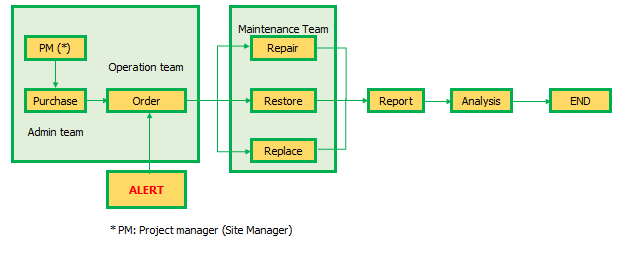

The main maintenance tasks, implemented by HBOM during the O&M process include:

1) Preventive Maintenance (PM): reduce problems by predicting possible problems. A thorough understanding of installed equipment, periodic inspections of equipment, and visibility into operational system trends are required for PMs.

2) Corrective or Reactive Maintenance (CRM) is to reduce the isolation time of Plant operation after failure. To minimize operational isolation, the Plant must be monitored for 24 hours without interruption; and systematize the monitoring work with full manuals, based on the data collected through our diverse experience, this monitoring will be run 24 hours to react with any incident.

3) Condition Based Maintenance (CBM) are routine activities performed for plant maintenance based on the normal operating condition of equipment. Some of the key CBMs include: modular cleanup management, and vegetation cleanup planning and collection of relevant meteorological information.